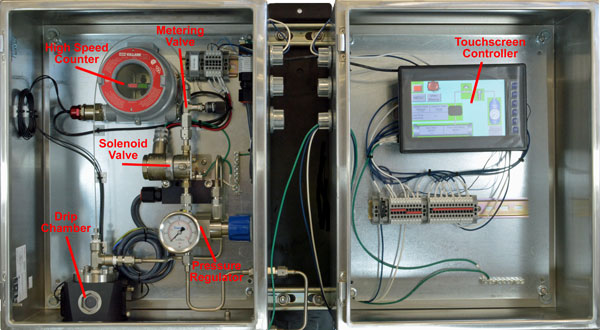

The following is the recommended preventative maintenance for the GPL 750 natural gas odorizer. These are guidelines and may vary depending on each site’s circumstances and performance history.

As with any equipment, it is imperative to follow the manufacturer’s maintenance schedule. Failure to do so can void the GPL Odorizer’s warranty.

GPL 750 Weekly Examination

- Check the odorizer for alarms (e.g., injection rate, solenoid life alarm)

- Assess the number of Auto Clears used.

- If half of the Auto Clears were used, search for the problem and try to resolve it.

- Verify that the settings are correct and the unit is odorizing the desired level.

- Check the regulators to ensure they are holding proper system pressure.

- Verify that the optics are calibrated. See calibrating the optical comparator.

Monthly Odorizer Check

- Confirm that the nuts and bolts are tight and the servo motor is not too loose or too tight.

- Check for visible signs of leaks.

- Sniff for extreme odor inside the box.

- Inspect the level gauge on the tank and assure it is moving.

Biannual Odorant Injection Inspection

- Inspect the tank for leaks or damage.

- Make sure the reservoir level is over 25%. If less, refill the tank.

- Remove the actuator and manually check the isolation valve for shut off.

- Remove the servo and inspect the metering valve for smooth operation.

- If the battery on the CPU is low, replace it.

Annual Odorization System Preventative Maintenance

- Check the power supply and make sure it is functioning correctly.

- Inspect the solar panels for chips, cracks, or other damage.

- Inspect solar batteries for damage.

- Change the odorant filter element.

- Replace the O-rings in the metering valve.

GPL 750 Odorizer One-Hour School

Image by Steve Buissinne from Pixabay.